Waterproofing two large residential buildings in SF

AVA Nob Hill

San Francisco

Two large residential buildings in SF were experiencing leaks, and Urban was called to investigate. In the course of repairing the leak, we discovered that some of the building panel joints had weak spots in the fragile EIFS lamina at the joint bondlines, leading to sealant failure and letting water in. What started as a mockup grew into applying the same waterproofing repair to the exterior of both buildings.

It is important that you keep water out of your building by ensuring all joints are fully caulked and the wall coating is sound and has the flexibility to perform and match the substrate movement. Once inside the wall cavity, water can create mold conditions and damage interior surfaces, causing expensive tenant relocation costs and mold remediation costs.

The ultimate repair scope, developed during the mockup phase, was applied to two large buildings spanning a city block. All building joints were caulked, including repairs to the EIFS substrate that was damaged or poorly installed originally. To complete the waterproofing, two coats of elastomeric coating were applied to the walls.

What We Did

Installed 150,000 square feet of elastomeric wall coating

Installed over 40,000 lf of sealant at building joints

Installed traffic coating in the garage elevator lobby.

Repaired numerous spalls, cracks, and weak spots in the EIFS substrate

Coated metal rails, doors, and other site metal with industrial metal coating

Project Details

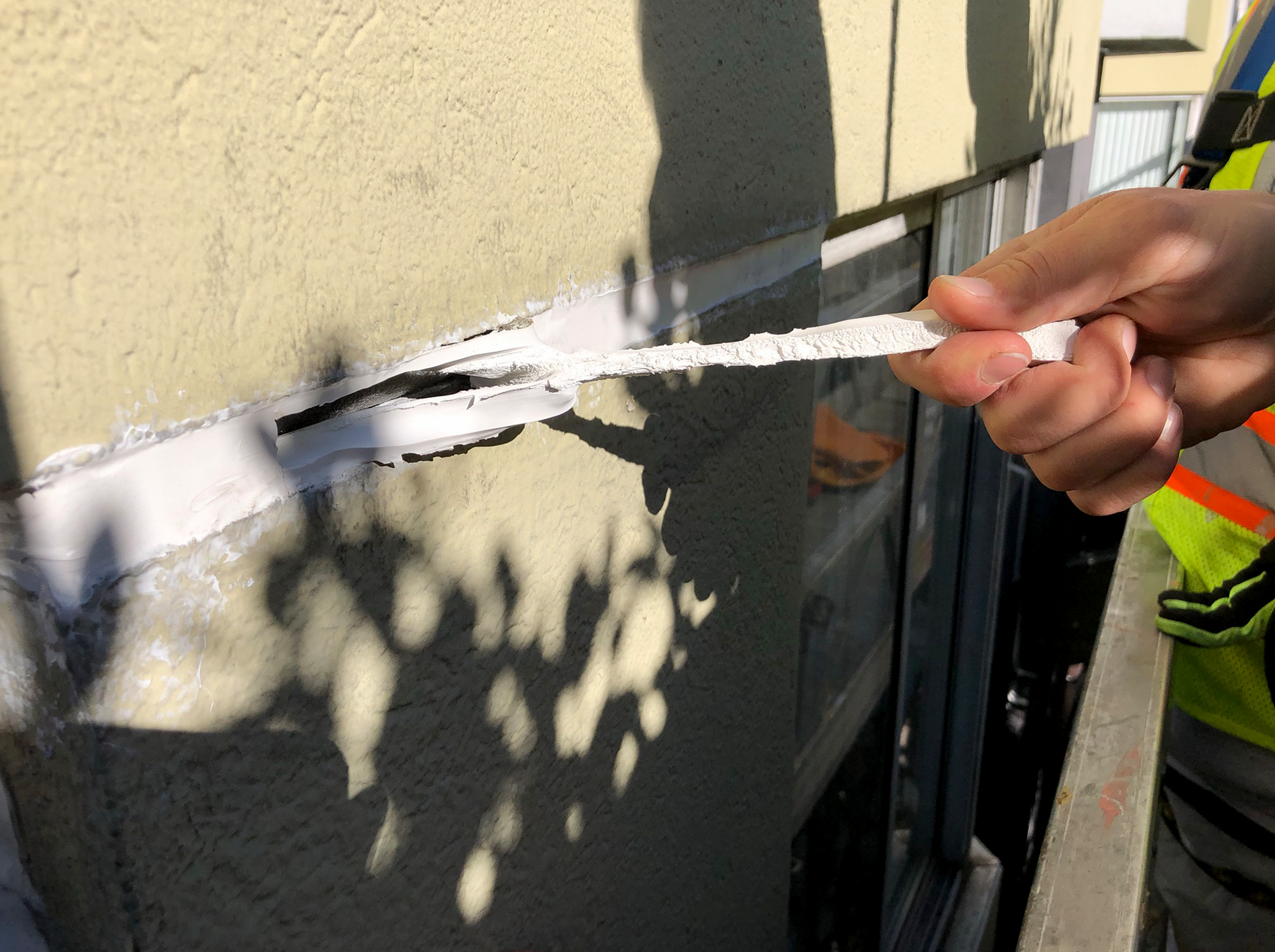

Between the two buildings, we accessed the building using more than 40 swing stage drops. All of the existing sealant in the building joints was carefully removed. With a soft substrate like EIFS (a combination of a 2” thick foam insulation board and a ¼” thick skin of repair mortar and mesh webbing, topped with a finish coat), you have to be careful not to create more damage when performing the repairs. This takes a very skilled technician with a light touch with the grinder.

With joint bondlines reinforced, new Sika HyFlex 150 hybrid dealant was installed—a paintable silicone variety—in all joints. All spalls in the EIFS were repaired, including foam replacement where needed, to render the building essentially watertight and paint-ready. Two coats of Sika 550W elastomeric coating were used to coat the walls, except for some areas that were at one time coated with silicone elastomeric. In those areas, we had to get a custom match and coat over with Dow All Gaurd silicone elastomeric. It was unusual to find those two coatings on the same building, but conditions dictated it. We wanted to make sure all the coating was going to stick for the long term.

A small added scope for the winter months out there: for the garage-level elevator lobby floor, we were asked to apply a urethane coating to the floor. First we had the floor shotblasted to clean it and provide profile, then we primed the floor and applied a urethane basecoat, a wear coat with sand broadcast, and finally a hard, aliphatic topcoat.

Fortunately, Urban had the service set to manage all of these building maintenance needs in one package.

Want to know how we can help with your next project?